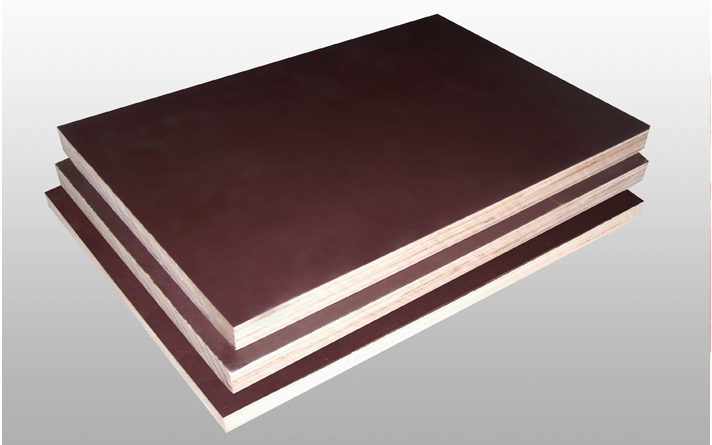

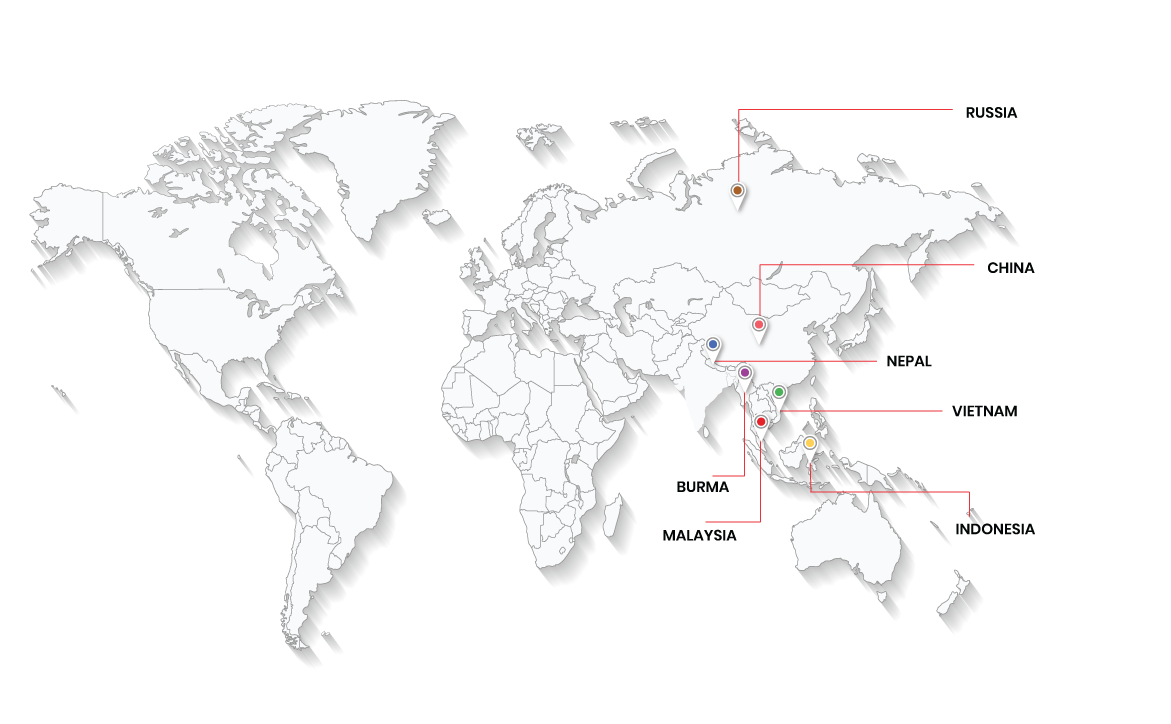

Welcome to Divya Ply, where quality meets innovation in interior design. Since 1996, we've led the industry as a manufacturer, supplier, and exporter of imported plywood and pine boards from Mumbai, India. With over 28+ years of legacy, we offer a diverse range of over 30 varieties of products, meeting ISO standards for assured quality. Our extensive dealer network of 1000+ partners ensures seamless distribution, supported by our 1,25,000 sq ft. warehousing capacity. Choose Divya Ply for reliability, durability, and unmatched service in interior design solutions.